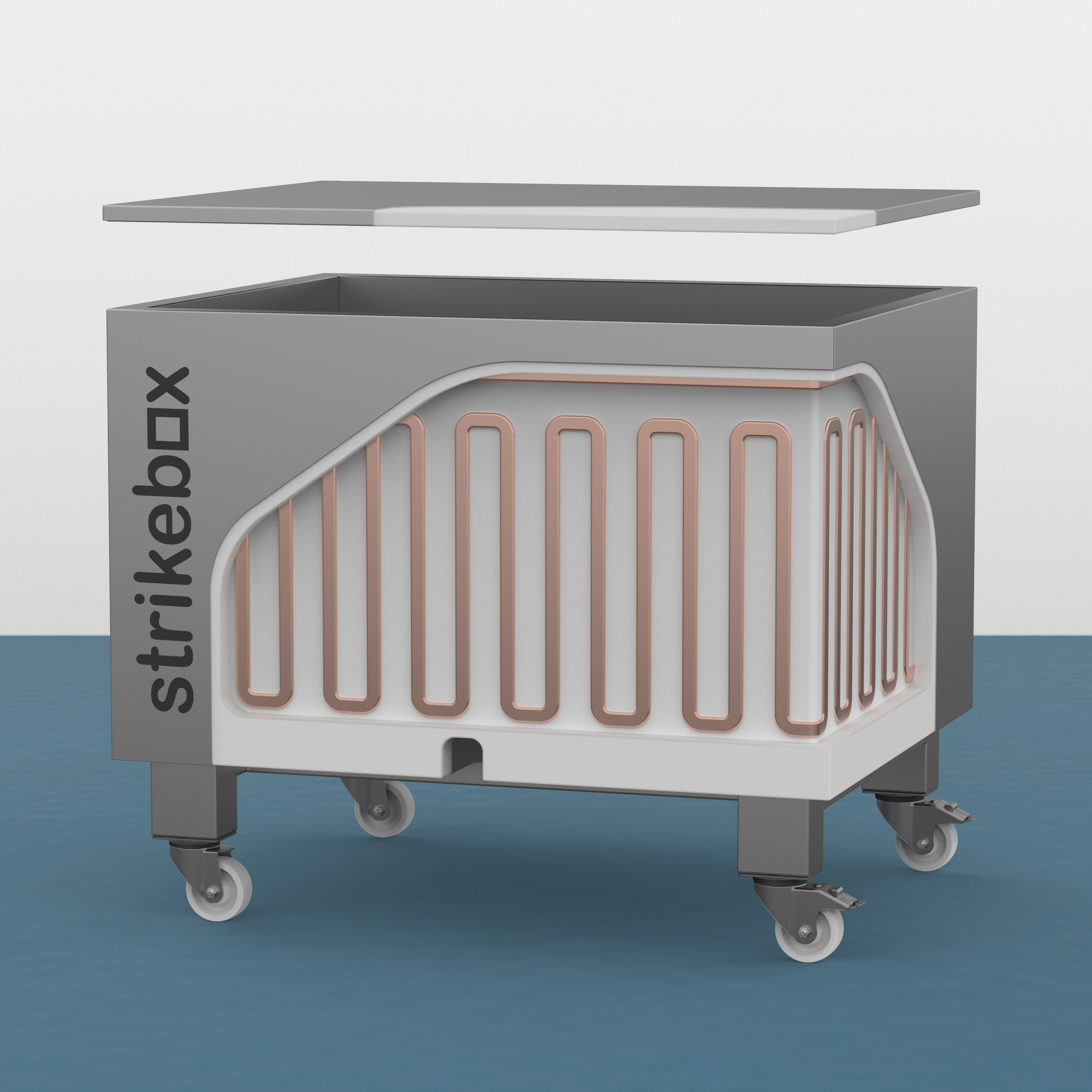

Jacketed totes are important components in processes where temperature stability, efficiency and effective energy management are key considerations. As engineers and consultants, we recognise that dimple jacket design is essential in ensuring process and heat transfer efficiency, and cost-effectiveness. With the right expertise and well-designed plates, businesses can streamline operations, maximise thermal exchange across different media.At Strikebox we use single embossed dimple plates, ensuring:

- High heat transfer coefficient with low pressure drops

- No surface damage on the inside of the tank due to the laser-welding process.

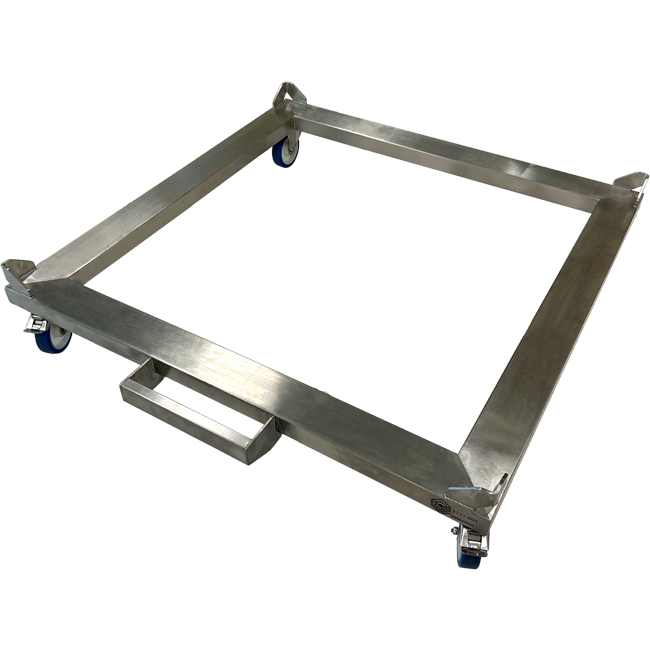

At Strikebox, we offer a wide range of solutions tailored to meet your specific mobile heating/cooling requirements. With experience in process design and optimisation for the bioprocessing industry, we collaborate closely with our clients to provide customised solutions that enhance safety and ergonomics, streamline processes, and optimise space usage.Temperature system, communicating technologiesOur Strikebox Heating Cooling Tote can be supplied with a temperature probe and display and our systems are equipped to communicate with the most common networks and PLC systems, including Ethernet/IP, DeviceNet, ControlNet, Profibus DP, Profinet, CC-Link, and Modbus TCP.