Client Overview

The client is a global leader in animal health, engaged in the discovery, development, manufacture, and marketing of medicines and vaccines for both livestock and companion animals. With a strong emphasis on research and innovation, the company operates in highly regulated environments, making reliability and compliance essential in every solution.

Project Objectives

The primary objective was to increase production capacity at the client’s existing facility, while continuing to use their current equipment and consumables. A key part of this upgrade involved introducing precise heating and cooling capabilities to optimise conditions for biological reactions and microbial growth, an essential factor in their process.

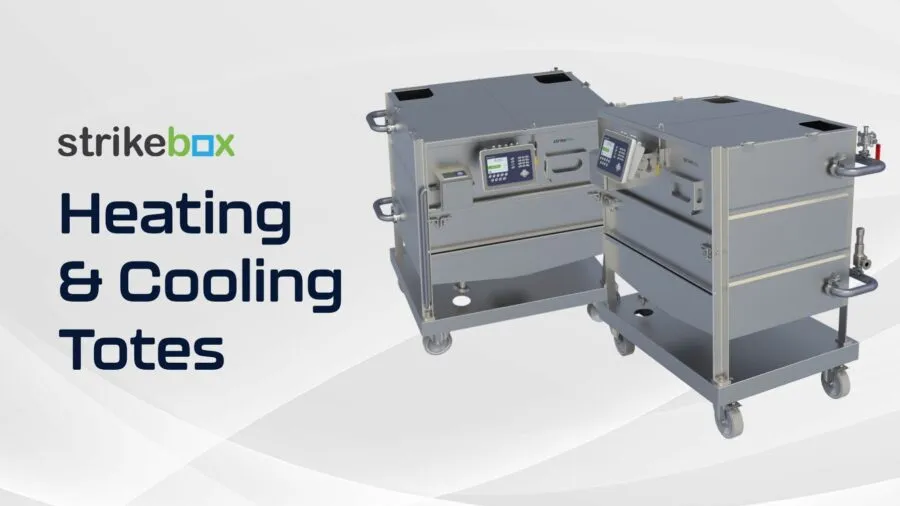

Our Solution

Strikebox proposed the design and manufacture of a series of custom stainless steel heating and cooling totes that were fully compatible with the client’s existing single-use (SU) bags. This approach avoided the need for extensive revalidation or the introduction of new consumables, significantly reducing cost and implementation time.

Process & Collaboration

Leveraging our extensive experience with SU bag integration and temperature control systems, we quickly identified the parameters critical to the project’s success.

Strikebox initiated the project with a comprehensive questionnaire to capture key technical and operational requirements. Following this, a collaborative TEAMS call was arranged with all relevant stakeholders to clarify specifications and align expectations.

We prioritise swift, clear, and effective communication throughout every project, ensuring alignment from concept through to delivery.

Challenges Overcome

One of the primary challenges was achieving accurate temperature measurement of the SU bag contents without compromising the validated design of the bags, which lacked built-in thermowells. Redesigning the bags would have significantly delayed the project and increased costs.

Our engineering team developed a removable external temperature probe that ensured direct contact with the bag surface while maintaining sterility and integrity, delivering reliable readings.

Additionally, both temperature and weight data needed to be integrated into the client’s existing SCADA system. Our team collaborated closely with the project management company and client representatives to develop a tailored hardware and software interface, enabling seamless communication with the plant’s control infrastructure.

Sustainability Considerations

The use of stainless steel enabled a fully reusable and easy-to-sanitise solution, aligning with both sustainability goals and industry hygiene standards. This approach reduced waste and extended the life cycle of key system components.

Circular Economy – Totes are a listed product on the Strikebox Take-Back Scheme eco initiative.

Safety

Given the nature of the closed jacket heating and cooling system, integrated safety features were essential. Pressure relief valves were incorporated into the design, and the dimple jackets underwent rigorous pressure testing prior to final approval and commissioning.

Test Results

Strikebox conducted initial performance testing using a Huber temperature control system to validate heating and cooling efficiency. The data was thoroughly analysed and presented to the client, confirming that the system met all performance expectations.